Model

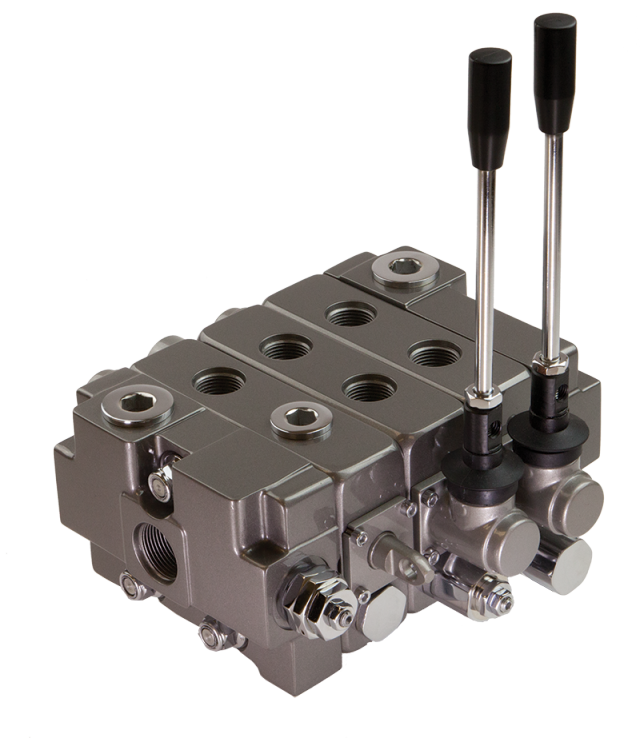

V130 DIRECTIONAL CONTROL VALVE

Description

|

Take control of your hydraulic system with Muncie Power Products’ V130 Series directional control valve. The V130 Series is constructed with high grade iron castings and nickel-plated spools for use in high pressure applications and can be configured with many different spool, control and positioner options. The V130 is designed for mid-range flow capacities, and offers superior performance in a compact package.

Muncie Power Products takes pride in supplying the work truck industry with the highest quality products and outstanding service & support. The V130 can be configured with custom options and controls, so if you don’t see what you need here, call today and let us put you in control of your hydraulic systems. |

|

KEY FEATURES & BENEFITS |

- High grade iron castings allow for high pressure capabilities for the most extreme applications

- Nickel plated spools resist wear allowing for long life under high pressure conditions

- Tight tolerances and precision machining keep internal, spool leakages low

- Internal oil core design allows for higher flow rates and low pressure drops, all in a smaller package

- High pressure carry over (power beyond) and closed center options available

- Load-checks are standard on all work sections

- Work port relief valves, anti-cavitation valves, combination R.V.’s/anti-cav valves and pilot operated check valves (lock valves) are available for your individual work section protection needs.

- Inlet relief valve is standard

- Parallel, series, tandem and metered spools available (lead times apply to non-standard options)

- Ability to combine valve families with custom mid-sections.

- Very versatile design can be configured with many different spool, control, positioner and accessory options

- Work sections are pre-assembled and 100% tested prior to shipping

|

|

SPECIFICATIONS |

|

TECHNICAL SPECIFICATIONS |

|

Design Type: |

Sectional |

|

MAX Work Sections: |

10 |

|

Circuit Types: |

Open center parallel, series, tandem and closed center |

|

Flow Capacity: |

Nominal: 21 GPM (80 LPM), Maximum: 30 GPM (114 LPM) |

|

MAX Pressure: |

1 - 3 Sections: 5075 PSI (350 BAR)

4 - 6 Sections: 4650 PSI (320 BAR)

7 - 10 Sections: 4350 PSI (300 BAR) |

|

MAX Back Pressure: |

365 PSI (25 BAR) |

|

Recommended Filtration: |

20/18/15 (ISO 4406:1999) |

|

Oil Viscosity Range: |

60 to 1950 SUS (10 to 400 cSt) |

|

Oil Temperature Range: |

-20 to 180 °F (-29 to 82 °C) |

|

Recommended Oil Temperature: |

85 to 140 °F (30 to 60 °C) |

|

Approx. Weights (std. options): |

Inlet: 1.5 lbs (2.3 Kg)

Outlet: 4.2 lbs (1.9Kg)

Work Section: 8.6 lbs (3.9Kg) | |

Get Directions

Get Directions

Get Directions

Get Directions